Welcome to our fourth blog, talking about how we can improve health and safety on construction sites. This blog discusses health and safety tech solutions that can improve site safety and help you to create a positive safety culture.

People consider working in construction high risk because of the nature of the work activities involved. The question to ask ourselves is can technology improve health and safety in the construction industry?

Can it help to prevent accidents? Can it support us with our compliance requirements? And can it lower that risk of working whilst on construction sites?

As we move into an era of digital transformation, organisations are now beginning to focus on using technology to improve site safety and the well-being of employees and contractors alike.

The Health and Safety at Work Act came into force back in October 1974, long before the digital age took hold. The Act is still in place after 48 years, with health and safety remaining important for successful organisations. How businesses go about achieving health and safety compliance has however, changed significantly.

Technology solutions for the construction industry

3D visualisation for construction safety: Many organisations are harnessing the power of technology alongside safety measures by integrating 3D visualisation tools. This innovative software is proving to be a valuable asset, heightening employees’ familiarity with their work surroundings and potential hazards.

High-Speed Communication: The integration of real-time data technology is revolutionising the safety of remote workers during their daily tasks. With a growing number of organisations embracing remote work with travel requirements, new challenges emerge. Prioritising employee safety remains crucial, and the swift exchange of information plays a pivotal role in achieving this goal.

Alongside this, journey management software stands out as an invaluable resource for employers dedicated to remote worker safety. Given the inherent risks associated with work-related travel, such software empowers employers to stay informed. It provides the capability to track when employees’ check-in at designated intervals, offering a proactive approach to managing potential risks.

Remote Worker Safety Technology: Tracking your lone workers’ locations and keeping them safe aren’t easy tasks. Lone worker technology in construction, with GPS tracking, reporting, and communication features can help you protect your workers and significantly reduce risk

Digital Health and Safety Management Systems: This can include the following electronic systems/portals to improve your organisations’ safety performance:

Safety reporting in construction: With just a few clicks on a mobile app or business cloud device, employees, contractors, and even the general public can quickly and easily log incidents, accidents, and near-misses.

Construction safety audits and inspections: With a user-friendly interface, you can create and conduct audits and inspections on the go, from any device.

Risk assessments and method statements: Manage risk assessments and method statements across your business and contractors with an easy-to-use electronic RAMS portal.

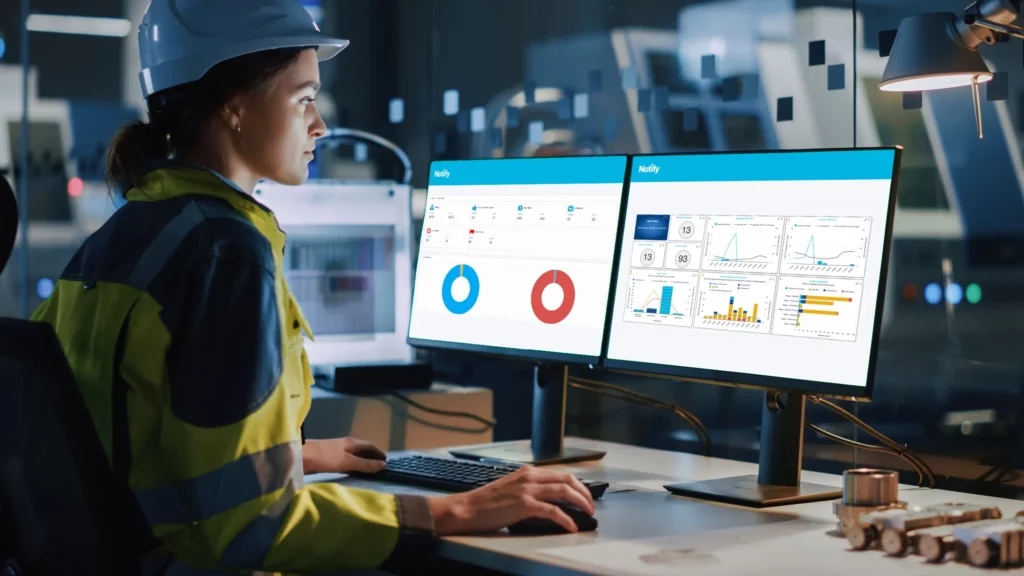

Safety intelligence: You can achieve real-time safety monitoring in construction through interactive dashboards. These dashboards also help with decision-making and reporting to the board.

Artificial Intelligence: You can an completely transform your occupational health and safety with AI. Improve hazard identification, predict possible risks, monitoring safety in real-time, spot unsafe behaviours, locate hazardous conditions, and proactively suggest ways to reduce potential risks.

How will technology solutions improve safety on construction sites?

The development and use of technology solutions in construction has already saved lives. It should be utilised by all construction companies to help prevent accidents and industries. In this part of the blog, we will delve into the use of digital health and safety management systems and how they can improve safety in construction.

Consistent safety procedures and document control

Using a digital safety management system ensures that your entire business, along with the connected supply chain, follows the right safety documents and procedures. This should be included in your business’s document control process, which keeps documents up-to-date with the latest statutory and best practice standards.

Increased visibility of safety compliance across the organisation

Obtain greater transparency across your business. Ensuring that all levels of management have clear visibility of their safety performance and safety compliance from anywhere.

Quicker and smarter safety reporting – less time spent by operational staff completing paper copies

Busy project management teams have traditionally spent a lot of time on health and safety compliance paperwork. Switching to a digital safety management system not only saves time but also lets managers and supervisors’ complete documentation on-site using their tablets or phones for daily or weekly records. An app can be downloaded on phones or tablets, allowing easy access, and editing of all records and reports while on-site.

Improved reporting data

Data is a vital component to understanding the risks facing workers and how to manage them. It’s also critical for engaging board members as it provides tangible evidence that can get their attention and commitment. Proactive risk management is also driven by data and gives health and safety teams the information they require to decide where the focus needs to be and what to do in order to reduce / prevent incidents.

Demonstrate criminal or civil compliance

The physical archiving of safety documents has always been a challenge for construction businesses. Currently the majority of small to medium business are archiving hard copies within a storage facility or employing someone to scan and upload all the documents at the end of a project.

With a digitalised system, all of your safety documentation will already be stored electronically and can be archived for a period in accordance with your documentation retention process. This digitalised approach will save you time and your businesses money. It will also eliminate the need for physical storage or administration fees for scanning and uploading.

Remote auditing

It is important for every business to monitor and report their safety performance to the Senior Management Team.

A digital system allows the Senior Management Team to monitor safety performance and compliance remotely. They can easily access safety data and statistics in real-time.

Save time during external audits (ISO/SSIP/Achilles Building In Confidence)

The majority of construction businesses are required to have SSIP (Safety Schemes in Procurement), or an equivalent accreditation that is submitted as part of a tender process. This is as a way of establishing competency within the construction sector.

A digitalised ehs system simplifies the certification process. All required evidence will be available on an electronic portal, making it easy to upload and submit information for approval. This will again save time and resource preparing for resubmission.

Deliver key safety briefings (toolbox talks/safe start briefings) via a phone or tablet

Quick access to registers, records and reports

All current safety forms/permits and registers can be created on a digital platform. They can also be made available to all workers and contractors with a click of a button.

Free learning events

Throughout my career, I’ve collaborated with various construction companies that have adopted digital health and safety management systems. These systems assist them in effectively managing both proactive and reactive safety strategies.

In every case, the near miss and hazard reporting has increased dramatically, meaning more data is available to learn from. As a result, this has helped those companies put preventative measures in earlier, helping to mitigate risk and potentially prevent accidents occurring in the future.

Corrective actions

Digital health and safety management systems will allow actions to be assigned as part of any incident investigation process or safety compliance audit. This will generate a notification to the assignee and will be left open until closed. All actions are recorded, addressed and tracked within the given time frame.

Overall, I do strongly recommend all construction businesses to investigate the adoption of construction safety management tools. There are some very clear advantages as I have listed above. I would further recommend a demonstration by Notify Technology – Health & Safety Software | Book a Demo | Notify (notifytechnology.com) to get a full understanding of what a digitalised safety management system could bring to your business.

Further blogs to follow in this series covering health and safety in the construction industry:

- Blog 1 – Why is Health and Safety important in construction?

- Blog 2 – What are method statements in construction?

- Blog 4 – Technology solutions for improving safety on construction sites

- Blog 5 – Prevent common injuries in the construction industry

References Used:

Construction – Construction Design and Management Regulations 2015 (hse.gov.uk)

The five elements of a successful data-driven safety culture – SHP – Health and Safety News, Legislation, PPE, CPD and Resources (shponline.co.uk)

Construction (Design and Management) Regulations – CITB