Construction is a dangerous industry, but technology can help to improve safety. Systems like fall detection and hazard monitoring can prevent accidents, while wearable sensors can monitor workers’ health. Find out how technology can improve safety in construction.

Here are some examples of how construction technology can improve occupational health:

- Building Information Modeling (BIM) can be used to create a digital model of a construction site, which can be used to identify and assess hazards before work begins.

- Wearable technology can be used to monitor workers’ health and safety, and to alert them to potential hazards.

- Augmented reality can be used to provide workers with real-time information about hazards, and to help them to work more safely.

- Robotics can be used to automate dangerous or repetitive tasks, which can help to reduce the risk of accidents and injuries.

Working at height

The Risk: Working at height presents numerous risks, including falling from scaffolds or ladders, falling through fragile roofs or skylights and injury from objects falling from a height.

Your Responsibility: According to the Health and Safety Executive, it’s the responsibility of those in charge of the site, (e.g. the contractor/construction company) to ensure the appropriate equipment is in place for the situation, whether it requires a ladder, scaffolding, a cherry picker etc. plus the correct protective measures such as side rails, toe boards, ladder inspections etc.

Method statements should be drawn up, to communicate clearly and concisely the hazards involved in specific work at height tasks and the risk and precautions required to all those involved in the work. These should be available to workers and supervisors.

How Tech Can Help: Keep workers and staff informed by setting up access to online storage, where personnel can retrieve the method statements, risk assessment documents, best practice documents and plans and permissions. This means that workers are unlikely to take any unnecessary risks when faced with a situation they’re unsure of, and it means that the precautions you have put in place are understood and more readily adhered to.

Moving Vehicles and Objects

The Risk: large industrial vehicles and heavy items/materials being moved around pose a risk of injury through vehicle collision or pedestrians being struck.

Your Responsibility: ensure that the site has been carefully planned, with clear separation of vehicle zones and pedestrian walkways. This may include ensuring that waste areas or storage areas are positioned so that vehicle routes never have to contact pedestrian routes and include turning circles so that vehicles don’t have to reverse, which is when most incidents happen.

Enforce a rule that all workers wear high visibility clothing on site, and of course, be sure that all drivers are in possession of the appropriate licenses and training.

How Tech Can Help: construction site planning software can help site planners to form practical and safe designs, ensuring that pedestrians are protected from vehicles, and traffic can move around the site without the risk of collision.

Slips, Trips and Falls

The Risk: construction sites are, by their very nature, places where buildings, walkways and paths are unfinished. Because of this, slips, trips and falls can be common. Hazards such as uneven ground, trailing cables, slippery surfaces and unguarded trenches or holes can all lead to injurious slips, trips and falls.

Your Responsibility: thorough and regular risk assessment should highlight areas of possible danger. Ensure you focus on the terrain that workers will be using, adapt to changes that weather can cause by gritting walkways in the case of ice or adding stones in the case of mud. Add signage, ramps and covers for particularly treacherous areas, and ensure that any trenches or holes are either covered or have guard rails, and always have clear signage. To avoid trailing cables, provide workers with cordless power tools where possible, and cover larger cables where they cross walkways.

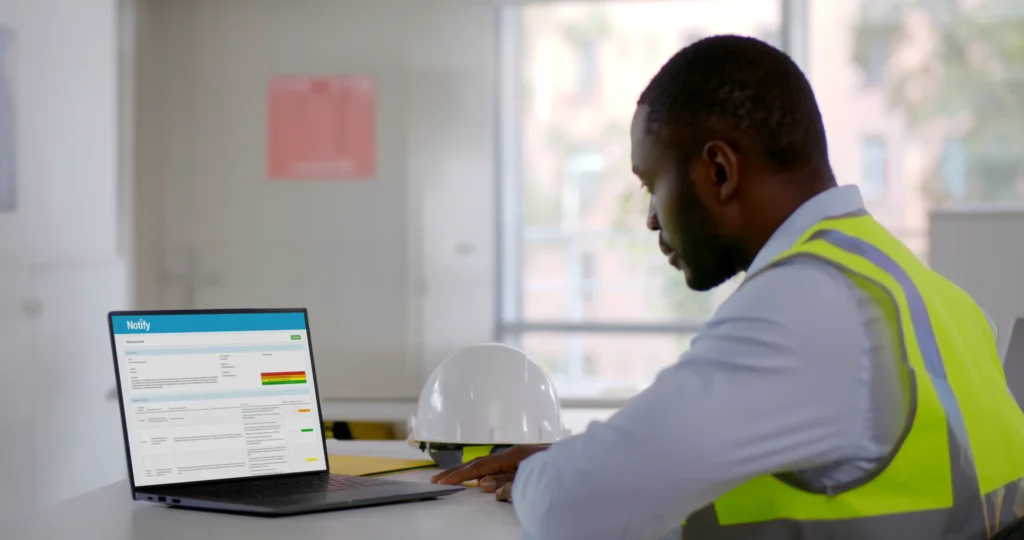

How Tech Can Help: while site managers aim to be as thorough as possible in their risk assessments and implementation of preventative measures, changing conditions and human error can cause some hazards to be overlooked, while workers on site might notice a hazard but be unable to report it before a serious incident occurs.

Using near miss reporting apps, like NotifyIM, workers can report hazards via their phone or tablet and can include pictures and details of location, all in under 60 seconds. This means that site managers can respond quickly, and implement safety measures to minimise further risk.

Material and Manual handling

The Risk: lifting and carrying heavy materials and objects can, when the correct methods are not used, cause serious injury.

Your Responsibility: providing regular manual handling training to all staff, highlighting the safest way to lift weighty objects.

How Tech Can Help: scheduling software can simplify the process of planning a training session with staff and can help you track that the practical training has taken place, and exactly which team members were present.

As well as this, looking at E-learning tools can help to make training more engaging and less consuming of resources, as well as automatically logging scores and completion of training.

Collapse

The Risk: during demolition or excavation projects, unplanned structural collapse can cause serious injury to personnel on site.

Your Responsibility: it’s important to ensure that structural surveys are carried out before work begins and throughout the process, and that professionals in possession of the correct training and competencies are assigned to carrying out these surveys. Careful planning and the use of appropriate safety equipment and structural support equipment is also vital.

How Tech Can Help: scheduling software, again, is a great way to ensure that regular surveys take place, as well as assign tasks to team members to ensure that safety measures are implemented.

Assessing exactly what equipment is needed for the job at hand, and how the equipment and measures needed might change as the project develops requires a thorough risk assessment. Software that allows you to build, update and distribute risk assessment documents can be helpful in ensuring that your documents are up to date and are available to all relevant parties.

Electricity

The Risk: electricity is potentially fatal when workers come into contact with live or damaged wires whilst working on site. Electricity is particularly dangerous as it’s often impossible to detect the danger beforehand, as it’s not possible to tell if a wire is live just by looking at it.

Your Responsibility: the law requires regular visual inspections of cables at the start of each shift. The electrical current must be isolated prior to work beginning (only in very specific situations can work be carried out on live wires). Plans should put in place when working near overhead power lines, and only qualified professionals should be allowed to work on electrics. Additionally, the electrical plans of buildings should be made available to all staff, so that they are informed of where on-site they might be at risk.

How Tech Can Help: As electricity is undetectable, it’s vital that you can be sure actions such as isolating the electrical supply and cable inspections have taken place. Using audits and inspection specific software, you can schedule inspections, assign tasks, and most importantly track that actions have taken place, so you can be sure vital tasks have been completed before potentially dangerous work takes place.

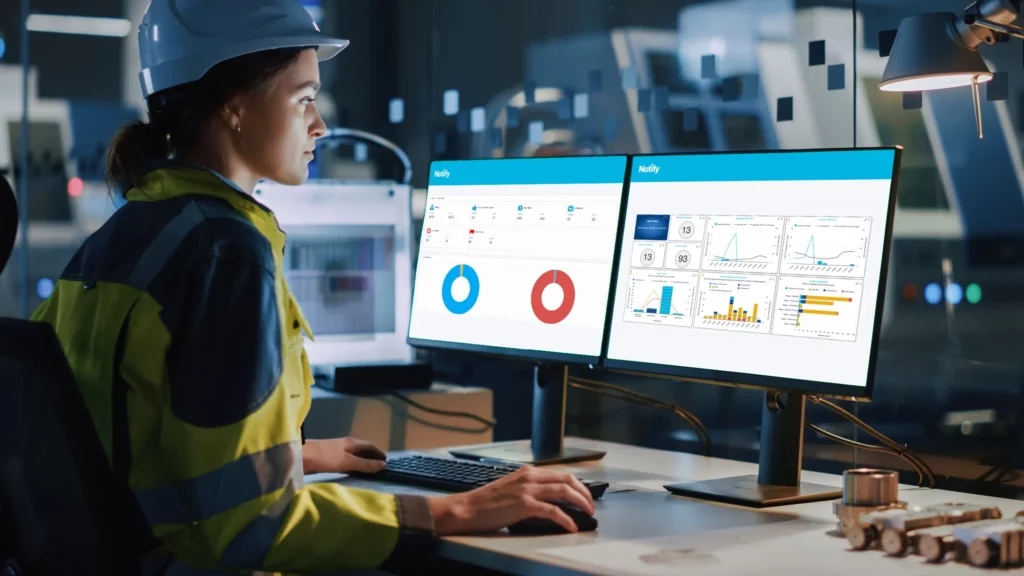

It can be difficult to implement technological solutions into processes that have been effective in the past. At Notify, we’re firm believers in the powerful benefits the use of software and applications can have on businesses.

Find out more here about how technology can benefit your Construction business’s health and safety processes.