Construction sites are a symbol of progress and growth, creating the buildings and infrastructure that shape our cities. But amidst all the hustle and bustle, we should never overlook one aspect: health and safety.

Health and safety in construction is more than just a legal requirement or a box to tick. It plays a crucial role in protecting the well-being and lives of workers. Construction sites are inherently hazardous environments, with numerous potential risks and dangers lurking around every corner. Construction workers face unique challenges like working at heights and handling heavy machinery, requiring proactive safety measures.

This blog talks about the importance of health and safety in construction. It also discusses the hazards and who should report unsafe practices. Additionally, it will also touch upon technology solutions for improving the safety and well-being of construction workers.

What does the HSE say?

In the past 30 years, the HSE has made rules for safety in construction work. These include;

- The Construction Design & Management Regulations 1994

- Construction (Health, Safety and Welfare) Regulations 1996

- The Working at Height Regulations 2005

- The Construction Design & Management Regulations 2007

- L144 – Construction Management (ACOP)

- The Construction and Management Regulations 2015 (current)

- L153 – Construction Management (Guidance)

The HSE created the regulations to ensure enforcement of duties and safety responsibilities. The goal is to ensure the safety and health of everyone. and to make sure that everyone stays safe and healthy.

The latest accident stats from HSE in Nov 2022 show that health and safety in construction is getting better. However, we still have some way to go to ensure that all employees and contractors go home safe and healthy. See below the current accident statistics:

Construction statistics in Great Britain, 2022 (hse.gov.uk)

What are the health and safety hazards in construction?

A construction site is a land area where workers are building or renovating roads, buildings, or some form of infrastructure. Working on a construction site involves using big machines and tools, working at high places, and being around dangerous materials.

Common construction site hazards include:

Working at height:

Working at height is the most common cause of fatal injuries to workers. The HSE reported that 51% of worker fatalities were due to a fall from height.

All employees who work at height need suitable training when working with different pieces of equipment. This includes working safely on ladders, scaffolding, and roofs. To prevent falls from height, you must also adopt safety approaches and precautions.

Moving objects:

A construction site is an ever-changing environment, with many objects moving around, often on uneven terrain. Delivery vehicles, heavy plant machinery and overhead lifting equipment pose a hazard to site workers and operators. Sites must always control the interaction between plants and pedestrians by using barriers and segregation when necessary.

Slips, trips and falls:

Slips, trips, and falls are a hazard on all construction sites. Contractors and sub-contractors on construction sites must manage work so that people can move safely around the site. Keep all sites clean and organised to prevent injuries from slipping, tripping, and falling.

Mental health:

Those in the construction sector are three times more likely to take their own lives than those working in other industries, according to recent publications (HSE/MIND UK). They are also six times more likely to die from suicide than a fall from height. A range of factors have led to these unsettling statistics, including pressures on the industry and stress of the work itself. Although people have become more aware, we still need to do more to enhance the mental health of workers in this industry.

Noise:

Working around loud, excessive and repetitive noise can cause long term hearing problems, such as deafness. Noise can also be a dangerous distraction and may distract the worker from the task at hand. This could then lead to an accident. You should conduct a comprehensive noise risk assessment to identify potential noise hazards in areas where work will be done.

Hand arm vibration syndrome (VWF – vibration white finger):

HAVS (Hand arm vibration syndrome) is a debilitating and painful disease of the blood vessels, nerves and joints. Continued use of hand-held power tools, including vibratory power tools and ground working equipment, typically causes it. HAVS can be prevented by proper planning. This includes reducing vibration exposure, monitoring workers, and providing suitable protection when using vibrating tools and equipment.

Material Handling – manual and by equipment:

Construction sites often move materials and equipment, either by hand or with lifting equipment, which can be risky.

Employees must receive training and a manual handling assessment to ensure safe lifting and carrying of materials.

For lifting equipment handling, there are lots of risks, especially when operating lifting equipment on uneven ground. Employers must train employees to safely operate lifting equipment and regularly test their competence. Always check if your plant is suitable, certified, and inspected before using it.

Airborne fibres and materials:

Construction sites unsurprisingly produce a lot of dust. This dust is often an invisible, fine, and a toxic mixture of hazardous materials and fibres (including asbestos). This can damage the lungs and lead to chronic obstructive pulmonary disease, asthma, silicosis and other such diseases. Recently the HSE have conducted a site inspection campaign across the construction industry, concentrating on respiratory risks and occupational lung disease.

People consider the construction industry to be a high-risk environment. When planning a construction site, make sure to identify all hazards and risks. Implement and enforce control measures to ensure everyone works and goes home safely.

Who is responsible for health and safety on construction sites?

Many people are important for keeping a construction site safe. From the client and principal designer to the dedicated workers and contractors, everyone has a responsibility to prioritise safety. The Construction Design & Management Regulations have detailed clear duties and responsibilities for all construction relation appointments since their introduction. These are as follows;

The Client – is responsible for providing pre-construction information and ensuring the competency of all appointments made with the project team.

The Principal Designer assists the Client with health and safety by ensuring that design risk assessments are conducted before construction commences. They are also responsible for liaising and communicating with all designers involved within the project.

The Principal Contractor is responsible for managing and controlling health and safety on the project, from start to finish.

The Trade Contractor must follow the Principal Contractor’s safety measures and agreed system of works (RAMS).

Operatives/workers must follow site rules and the safe system of works. In addition, they also have a duty to report site hazards and to cooperate with their employer.

Who is responsible for reporting unsafe practices?

In the construction industry, we all have a shared responsibility to keep each other safe. When reporting unsafe practices, certain important individuals are involved to ensure a safe work environment.

First and foremost, it’s important for employees to be proactive in reporting any hazardous conditions or unsafe behaviours they come across. If they notice something wrong, they should immediately inform their supervisor or the designed safety staff member on site. This will allow them to quickly address and resolve the issue. Prompt reporting could prevent accidents and protect fellow workers on site.

Contractors and subcontractors also have an important part to play. As stakeholders in the construction process, it’s essential for them to keep a watchful eye on their work areas. If they notice any safety concerns or potential hazards, they should report them.

Additionally, regulatory bodies like the Health and Safety Executive (HSE) are there to ensure compliance with health and safety regulations. They rely on reports of unsafe practices to take necessary actions. If you come across any safety violations that need attention, don’t hesitate to report them to the appropriate authorities. Your report can initiate investigations and prompt the taking of corrective measures.

Remember, we all have a role to play in keeping the construction industry safe. By reporting unsafe practices, we work together to prevent accidents, injuries, and create a culture of safety. Together, we can make a difference and ensure a secure working environment for everyone.

How can technology be used to improve health and safety in the construction industry?

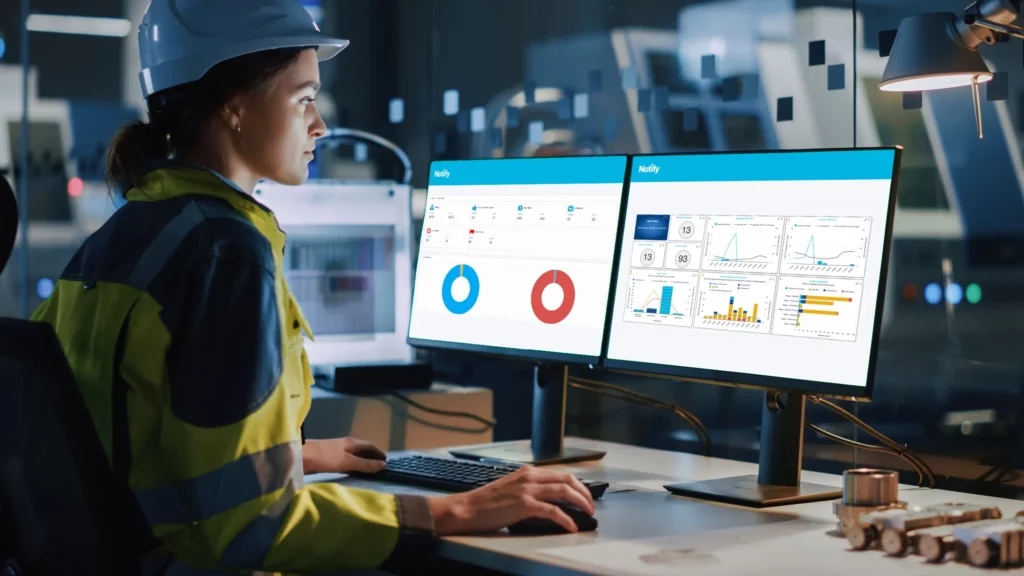

Technology has an important part to play in ensuring health and safety compliance within the construction industry moving forward. Using technology to eliminate paper and simplify reporting and recording is crucial for our safety management system.

More and more businesses are using technology to improve their safety compliance. When it comes to near miss/hazard reporting for example, I have seen many different procedures, from paper registers to close call cards, but in my opinion, the most effective has been electronic versions, such as Notify’s Incident Management module.

In the past when I have questioned operatives/supervisors/managers why they have not reported a near miss or hazard events, I had been informed that they are too busy and do not have the time to complete a written report. An electronic reporting system can make this process quick for all users and recipients. I have seen the number of near miss and incident reports grow hugely in a number of organisations as a result of implementing a digital system. As a results of the learning from these reports, this in turn has helped those companies significantly reduce the number of lost time and reportable incidents.

Further blogs to follow in this series covering health and safety in the construction industry: