Effective management of Health and Safety risks in the engineering industry means being aware of the numerous potential hazards to your team. From the risks associated with operating heavy machinery to the use of harsh chemicals, the potential injuries and illnesses that can occur in engineering environments can be life-threatening.

Managing these risks and protecting your team can be a complex job with a heavy workload. The risk assessment of many different processes, the inspection and servicing cycles of different units of machinery and systems, keeping on top of training and ensuring licenses are up to date – it can feel like a struggle to manage it all.

In the spirit of helping you effectively protect your team and uphold compliance whilst maintaining your own sanity, we’ve listed the top five health and safety risks in the engineering workplace and provided some helpful tips on how to manage them effectively.

Machinery Risks

In engineering, injuries and cases of ill health involving machinery measure in the thousands each year. With different pieces of machinery for different engineering processes, keeping on top of managing the health and safety measures associated with each can be time-consuming. Here are some elements to consider:

- Maintenance – keeping your machinery in good condition and good working order is vital. Malfunctioning or poorly maintained machinery can pose a serious health and safety risk, so ensure your machines are in good working order by conducting daily inspections, and ensuring they receive regular servicing and auditing.

- Safeguards and safety equipment – many machines will have safety mechanisms installed including emergency stops and guards. It’s important to ensure these are installed correctly and are in good working order, so it’s important to include these elements in your regular inspections of machinery and servicing routines.

- Training – it’s vital to ensure that anyone using the machinery in your business is fully trained and possesses any required licences. This not only protects those using the machinery but also ensures your business’s compliance, so keeping on top licence and training renewals (including first aid training) will keep your workers safe and your business within the law.

- PPE/clothing – Ensure your team are equipped with the appropriate PPE for the job at hand, including safety goggles and head protection. It’s important to ensure that machine operators are wearing suitable clothes and are not at risk of becoming entangled in the machinery, so instruct your team to limit baggy clothing/wear overalls, tie long hair back in hairnets, and remove jewellery. In general, the use of gloves next to engineering machinery such as lathes, drills, and other rotating-style equipment is considered dangerous due to the increased risk of entanglement.

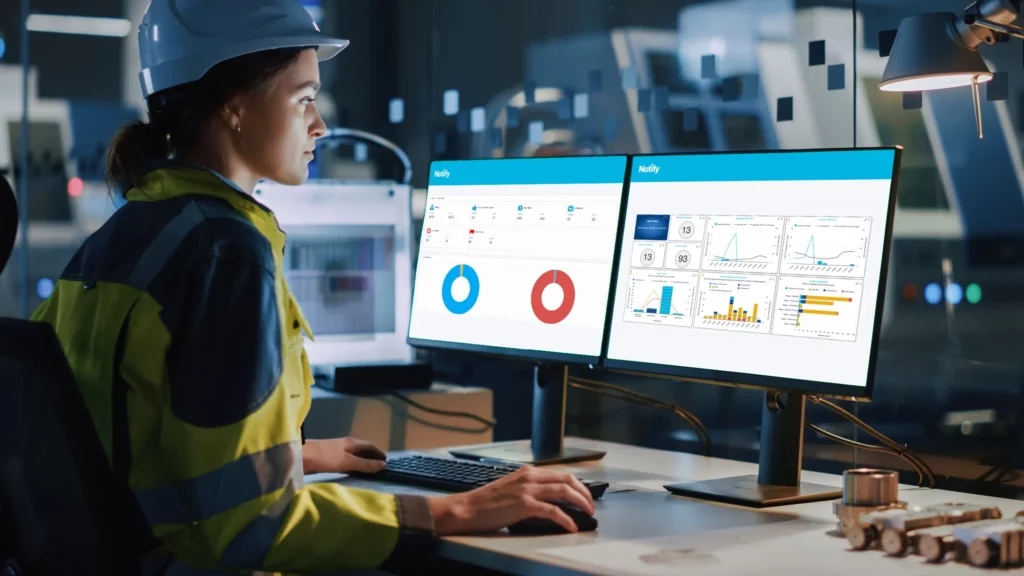

Risk Management Tip: Scheduling software – scheduling software can help you keep on top of the various inspection, servicing and auditing cycles of your machinery, ensuring you maintain compliance and can spot any problems quickly. It can also help you with renewing training and licences for staff and make sure your team is fully qualified to use the equipment.

Vehicle Risks

Many of the vehicle related injuries in the engineering industry are caused by delivery lorries or fork-lifts. While some incidents are unavoidable, the large majority of health and safety incidents can be prevented with some simple measures:

- Site Rules – drivers who are unfamiliar with your premises or the site you’re working on will need clear signage to indicate your site’s traffic rules. Often, incidents occur whilst lorries are reversing or due to unclear traffic rules leading to a collision with other vehicles or pedestrians. Ensure your site has a safe planned route for delivery drivers and that it’s clearly communicated.

- Site Planning – careful planning of your site is required to ensure that vehicles and traffic routes are separated from pedestrian routes in order to prevent injuries from a collision. Ensure pedestrian routes are clearly marked and any points where it is necessary for vehicle and pedestrian routes to intersect should be clearly signposted and situated at well-lit, clearly visible points.

- Forklifts – forklifts need to be kept in good working order and included in your health and safety audits and inspections. Only drivers who are trained and authorised to use the vehicle should be driving them, as untrained drivers are likely to cause accidents. Ensure that the forklifts used are suitable for the job at hand and that drivers are given enough time to complete the required work – pressured environments are where dangerous mistakes are more likely to be made.

Risk Management Tip: Incident Reporting Apps can help enormously with managing Health and Safety risks in Engineering. Data that is collected from incident, accident and near miss reports can be used to identify areas where further health and safety measures are needed.

Using incident managment reporting technology such as a mobile app means that the barriers towards staff reporting incidents are broken down, and you can gather and analyse data to identify where future incidents may occur, and how to prevent them.

Slips, Trips and Falls

Engineering workplaces can be messy with oil, dust and other waste from machines and work processes. As well as this, slips, trips and falls are made all the more dangerous with the risk of falling into machinery or sharp edges. Managing these risks effectively needs attention to detail to identify potential risks.

- Risk assessment – as with any work environment, careful, detail-driven risk assessment is required. For slips, trips and falls this requires careful surveying of the environments your team will be working in for any potentially dangerous features such as uneven flooring, uncovered blades, wobbly handrails or unfenced drops.

- Oil – machinery used in engineering can leak oil and cause slip hazards for your team. Ensuring your machines are in good working order will limit the amount of oil that is leaked, and installing a containment system to catch the leaked oil can keep it away from walkways and work areas, protecting your team. As an added bonus, collected oil can be reused, saving your company money.

- Dust – some processes produce dust and particles that can make an otherwise well-gripped floor dangerously slippery. The amount of dust that ends up on the floor can be reduced by rethinking processes, however wherever dust is produced a small amount will inevitably make its way onto the floor. Testing your flooring for grip and the effect that dust or other substances your processes produce has on it can help you identify whether new flooring is required to protect your team.

Risk Management Tip: Risk Assessment Software – Specialist software can streamline the risk assessment process, allowing you to not only save time and resource but also make risk assessment documents shareable to relevant members of your team and collaboratively update your documents as safety measures are implemented.

Electricity and Switchgear

Switchgear and electrical equipment, when maintained properly and used correctly, is generally very safe. The reason it’s one of the most common health and safety risks in Engineering is that when things go wrong, it can go catastrophically wrong, leading to fatalities, life-long illness or serious injury.

Some important things to consider when dealing with health and safety around electricity and switchgear are:

- The age of the Equipment – while it’s not a legal requirement to replace old equipment such as oil circuit-breakers, many businesses are upgrading to more modern alternatives, such as vacuum breakers. There are many reasons for this, but one important one is that newer equipment is easier to maintain. The expertise and replacement parts required to manage older equipment aren’t as easy to find, and newer equipment must fall in line with regulatory requirements.

- Training – many of the incidents that occur around electrical equipment and switchgear are due to a lack of knowledge on the part of the operators and staff. Ensure everyone working on site is aware of the potential risks around your electrical equipment by scheduling training sessions, then ensure training logs are adequately updated.

- Overstressed equipment – ensure your equipment is rated to deal with present-day current loads and fault levels. Older equipment may not have been designed for the amount of power modern work practices use, so testing the voltage both upstream and downstream of your switchgear, and how your equipment is coping, can prevent serious incidents occurring.

- Maintenance – ensuring your equipment is kept in good working order is essential. This means regular inspections carried out by capable people who have the expertise and knowledge to spot faults or potential risks in your equipment.

Risk Management Tip: Action tracking software can help make managing the different tasks that go into ensuring your switchgear and electrical equipment is safe far simpler. Keeping track can be complex, and when things get busy, important tests, training or inspections can be overlooked. Investing in software that allows you to assign team members to certain tasks, track progress, send automatic reminders and escalate when necessary means that you can be sure important actions are completed.

Manual Handling

In engineering, manual handling is an everyday task that your staff will need to be completing safely time and time again. Certain factors can affect how safely your team can move heavy objects around site.

- Training – as with any industry where large, unwieldy or heavy objects need to be moved by staff, manual handling training needs to be in place to ensure your team are not putting themselves at risk of injury. Ensuring this is provided at regular intervals means you can be sure your business maintains compliant.

- Environment – ensure the route your staff need to take whilst carrying large, heavy or unwieldy objects is clear of any obstacles or potential hazards. Stairs, sharp corners, nearby machinery, slippery floors or narrow walkways can all increase the risk of injury whilst moving objects, so risk assessing the routes your staff need to take while loading/unloading goods or equipment can protect your team.

- Sharp edges – unfinished and sharp edges on objects that need to be carried can cause injury both to those who are carrying the object, and anyone nearby who could come into contact with it. Ensure that edges are finished or protected to help your site remain injury-free.

Risk Management Tip: Share best practice documents. Making your risk assessments, best practice documents and training materials shareable means that your team can access any information they may need while carrying out their work from their mobile devices. This can mean that time is saved as best practice information is readily available, and fewer risks are taken in an effort to get them done quickly, as information can be accessed quickly and easily.